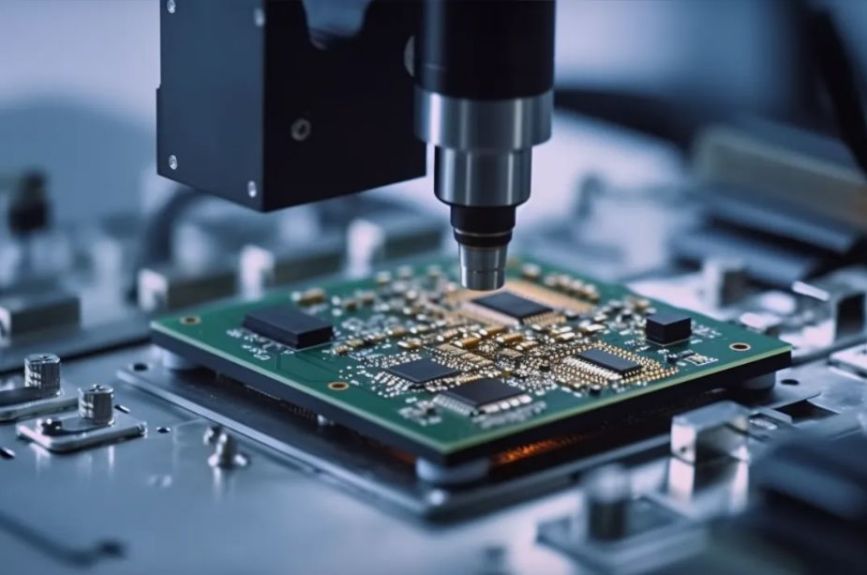

Khamphani ea theknoloji e phahameng ea semiconductor e sebetsa ka thata ho phethela taolo e ikemetseng ea mahlale a bohlokoa a ho kopanya li-semiconductor, ho felisa monopoly ea nako e telele ea ho reka kantle ho naha lihokelong tsa ho paka le ho leka li-semiconductor, le ho kenya letsoho ho beheng lisebelisoa tsa bohlokoa tsa ho paka le ho hlahloba li-semiconductor.

Phephetso ea Morero

Mokhoeng oa ho ntlafatsa boemo ba ts'ebetso ea lisebelisoa tsa mochini oa ho kopanya, ts'ebeliso ea lisebelisoa tsa motlakase ka boiketsetso e se e le senotlolo. Ka hona, joalo ka karolo ea bohlokoa le setsi sa taolo ea lisebelisoa tsa mochini oa ho kopanya, taolo ea motlakase ke karolo ea mantlha ho netefatsa ts'ebetso e tsitsitseng, e tšepahalang le e sebetsang hantle ea lisebelisoa.

E le ho fihlela sepheo sena, khamphani e hloka pele ho khetha sehlahisoa se loketseng sa phepelo ea motlakase sa khabinete ea taolo, 'me lintlha tsa bohlokoa tseo u lokelang ho li nahana li kenyelletsa:

01. Bophahamo ba phepelo ea motlakase

02. Motlakase le botsitso ba hona joale

03. Khanyetso ea mocheso oa phepelo ea motlakase

Tharollo

Phepelo ea motlakase ea WeidmullerPROmax ea mohato o le mong e fana ka litharollo tse reretsoeng litsebi bakeng sa lits'ebetso tsa othomathike tse nepahetseng joalo ka li-semiconductor.

01Moralo o monyane,

Mojule oa matla a fokolang oa 70W ke bophara ba 32mm feela, e leng se loketseng haholo sebaka se moqotetsane ka hare ho khabinete ea bonding.

02Ka botšepehi sebetsana le ho feta tekano ho fihlela ho 20% kapa mojaro o phahameng oa 300%,

lula o boloka tlhahiso e tsitsitseng, 'me u fihlelle bokhoni bo phahameng ba ho phahamisa le matla a felletseng.

03E ka sebetsa ka mokhoa o sireletsehileng tikolohong ea mocheso o phahameng oa khabinete ea motlakase,

esita le ho fihlela ho 60°C, 'me e ka boela ea qalisoa ka -40°C.

Melemo bakeng sa bareki

Kamora ho amohela phepelo ea motlakase ea WeidmullerPROmax ea mohato o le mong, k'hamphani e rarollotse matšoenyeho mabapi le phepelo ea motlakase oa taolo ea lisebelisoa tsa mochini oa semiconductor bonding, 'me e fihletse:

Boloka sebaka se ka hare ho khabinete haholo: thusa bareki ho fokotsa sebaka sa karolo ea phepelo ea motlakase ka hare ho khabinete ka hoo e ka bang 30%, le ho ntlafatsa sekhahla sa tšebeliso ea sebaka.

Finyella ts'ebetso e tšepahalang le e tsitsitseng: netefatsa ts'ebetso e tšepahalang le e tsitsitseng ea likarolo ka har'a khabinete eohle ea motlakase.

Kopana le tikoloho e thata ea mosebetsi ea khabinete ea motlakase: felisa matšoenyeho mabapi le lithibelo tse kang ho futhumatsa le ho kenya moea ha likarolo.

Tseleng e lebisang sebakeng sa lisebelisoa tsa semiconductor, lisebelisoa tsa ho paka le ho leka tse emeloang ke mechini ea ho kopanya li hloka ho ntlafatsa boemo ba tsona ba tekheniki ka potlako. Mabapi le ho fihlela litlhoko tsa othomathiki ea motlakase ea lisebelisoa tsa mechini ea ho kopanya, Weidmuller, ka boiphihlelo ba eona bo tebileng lefapheng la khokahano ea motlakase le litharollo tse etellang pele tsa phepelo ea motlakase ea indasteri, e fihletse litlhoko tsa bahlahisi ba lisebelisoa tsa ho paka le ho hlahloba tsa semiconductor tsa malapeng bakeng sa lik'habote tsa motlakase tse sebetsang hantle, tse tšepahalang haholo le tse nyane, e tlisa letoto la litekanyetso tse ncha ho bahlahisi ba lisebelisoa tsa ho paka le ho hlahloba tsa semiconductor.

Nako ea poso: Phuptjane-14-2024