Bakeng sa bareki ba indastering ea peterole, petrochemical, metallurgy, motlakase oa mocheso le liindasteri tse ling tse sebeletsoang ke k'hamphani e etellang pele ea motlakase Chaena, lisebelisoa tse felletseng tsa motlakase ke e 'ngoe ea litiisetso tsa motheo bakeng sa ts'ebetso e boreleli ea merero e mengata.

Ha lisebelisoa tsa motlakase li ntse li eketseha ka dijithale, li le bohlale, li na le modular ebile li kopantsoe haholo, theknoloji e etellang pele ea khokahano ea motlakase e tla phetha karolo ea bohlokoa haholoanyane likarolong tsa bohlokoa tsa motlakase le phetisetso ea matšoao.

Liphephetso tsa Morero

E le ho fana ka merero e felletseng ea motlakase hamolemo ho beng ba ho qetela, k'hamphani e tšepa ho khetha sete ea litharollo tsa khokahano ea motlakase ea boleng bo holimo ho netefatsa phetiso e tšepahalang ea motlakase le matšoao. Mathata ao e tobaneng le 'ona a kenyelletsa:

Mokhoa oa ho eketsa polokeho ea likhokahano liindastering tse kang lik'hemik'hale tsa petroleum le matla a mocheso

Mokhoa oa ho ntlafatsa ts'epo ea khokahano

Mokhoa oa ho sebetsana le litlhoko tse fapaneng tsa khokahano tse ntseng li eketseha

Mokhoa oa ho ntlafatsa litharollo tsa theko ea sebaka se le seng haholoanyane

Tharollo ea Weidmuller

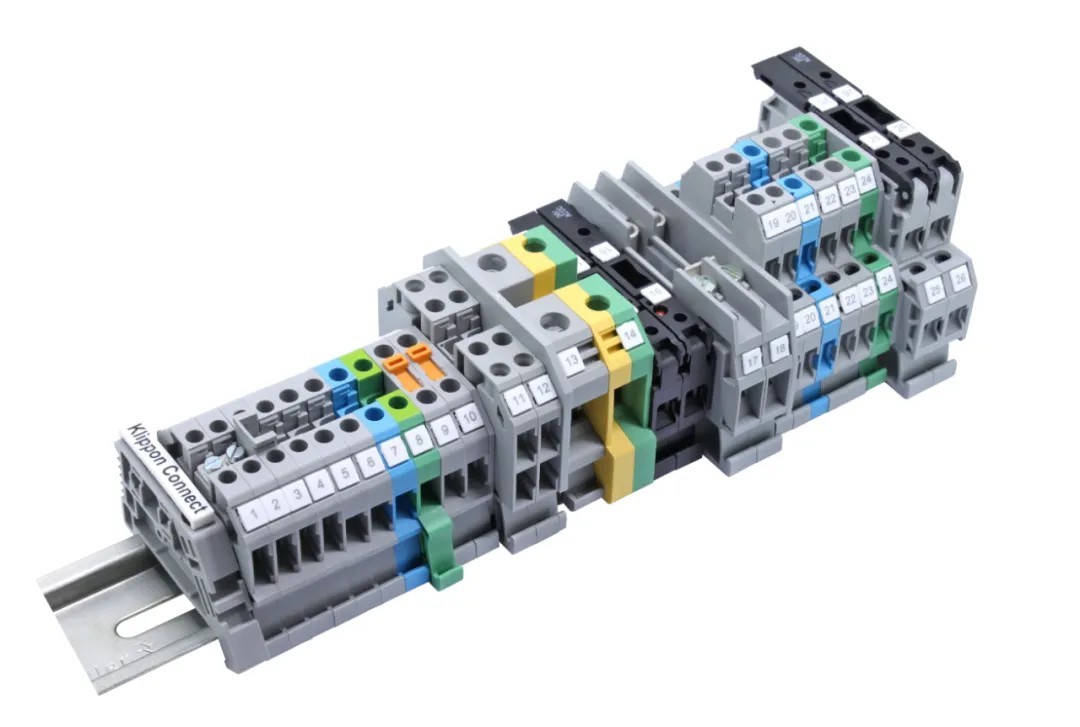

Weidmuller e fana ka sete ea litharollo tsa khokahano ea letoto la SAK tse sireletsehileng haholo, tse tšepahalang haholo le tse fapaneng bakeng sa merero e felletseng ea motlakase ea k'hamphani.

Liboloko tsa terminal tse entsoeng ka thepa ea boleng bo holimo ea ho thibela mocheso

Ka sehlopha sa VO se thibelang malakabe, mocheso o phahameng ka ho fetisisa oa ts'ebetso o ka fihla likhato tse 120 tsa Celsius.

Theknoloji ea khokahano e thehiloeng holim'a foreimi ea crimping

Matla a ho hula a mangata, motlakase o fokotsehileng, thibelo e tlase ea ho kopana, le litšobotsi tse se nang tlhokomelo.

Mefuta e fapaneng ea lihlahisoa

Joalo ka mofuta o otlolohileng, mofuta oa ho thella, mofuta oa mekhahlelo e 'meli, jj., e loketseng litlhoko tse fapaneng tsa ts'ebeliso.

Tlhahiso le phepelo ea lehae

Finyella maemo a boleng ba lefats'e ka bophara 'me u fihlelle tlhoko ea bareki ba lehae ea nako ea ho tlisa thepa.

Melemo ea bareki

Tiisetso ea polokeho

Theknoloji ea khokahano ea motlakase e netefalitsoe ka polokeho, e nang le thepa e matla ea ho thibela malakabe le ho thibela malakabe, e fokotsang haholo kotsi ea likotsi tsa polokeho tse kang mollo kapa potoloho e khuts'oane.

Botšepehi ba khokahano

Theknoloji ea ho kenya lithapo tsa foreimi e kobehileng e na le matla a holimo a ho khomarela, e leng se fokotsang mathata a kang ho hlepha kapa ho se kopane hantle, 'me se ntlafatsa haholo ts'epo ea khokahano.

Ho fihlela litlhoko tse fapaneng

Mefuta ea lihlahisoa tsa khokahano e ruile 'me litlhaloso li pharaletse, li fihlela litlhoko tsa bareki bakeng sa likhokahano tse fapaneng tsa motlakase.

Ntlafatsa bokgoni ba ho fana ka thepa

Finyella litlhoko tsa bareki tsa ho tlisa thepa bakeng sa theko e kholo le ho ntlafatsa haholo bokhoni ba ho tlisa thepa ea projeke

Phello ea ho qetela

Lisete tse felletseng tsa lik'habote tsa motlakase ke tiisetso ea motheo bakeng sa ts'ebetso e tloaelehileng ea mechini le lisebelisoa liindastering tse fapaneng. Ha theknoloji ea lisebelisoa tsa motlakase e ntse e tsoela pele ho hola, Weidmuller, ka boiphihlelo ba eona bo bongata lefapheng la likhokahano tsa motlakase ho theosa le lilemo, e ntse e tsoela pele ho tlisa litharollo tsa khokahano ea motlakase tse sireletsehileng, tse tšepahalang, tse felletseng le tsa boleng bo holimo ho bafani ba lisebelisoa tse felletseng tsa motlakase, e ba thusa ho ntlafatsa tlholisano ea bona ea 'maraka le ho ea mehleng e mecha ea lisebelisoa tsa motlakase.

Nako ea poso: Mphalane-12-2024